An intelligent supply chain topology modeling and cost analysis solution for SCM planning teams and business consultants to simulate cost, time and carbon-footprint flows across the SCM network and undertake “what-if” analysis scenarios to optimize supply chain network.

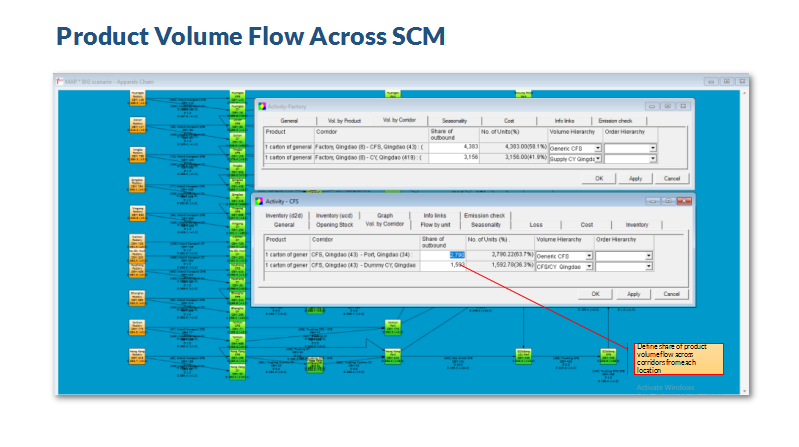

The solution helps in modelling/simulating a supply chain network and define flows related to Product/volume, cost, lead-time and carbon emissions across the value chain.

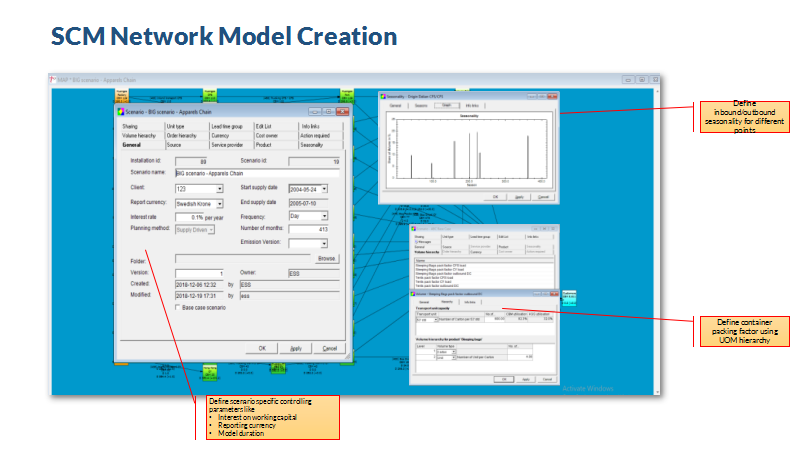

- This will allow Trade or supply-chain planning teams to define or optimize the overall cost expenditure and lead-time requirements across the chain by tweaking different parameters like CFS pack factors, volume split, interest rates, incoterms, etc.

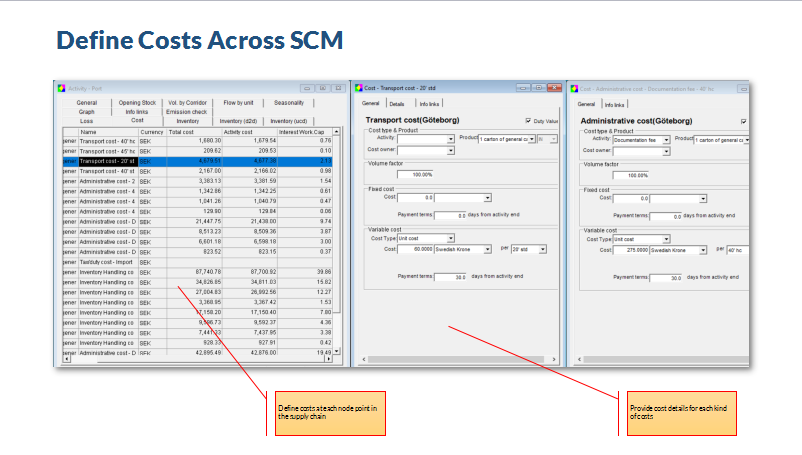

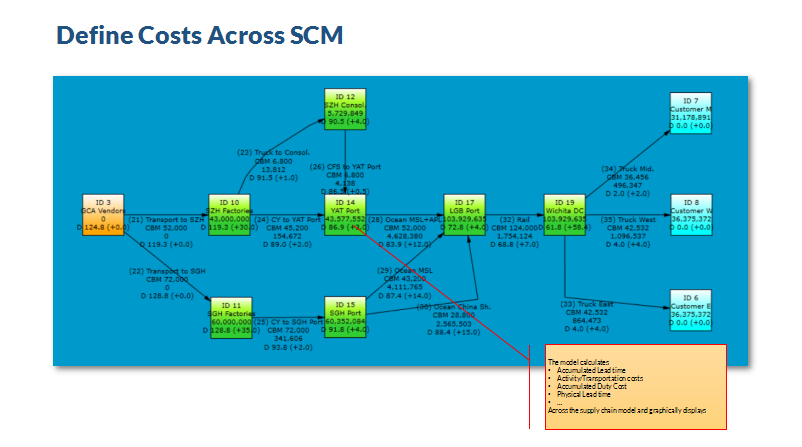

- It models detailed cost flows for multiple products across the supply chain network including Purchase Costs, Interest on Working Capital due to payment terms, Seasonality driven inventory-handling costs, import duties & taxations, transportation costs, losses/pilferage and various warehouse handling costs.

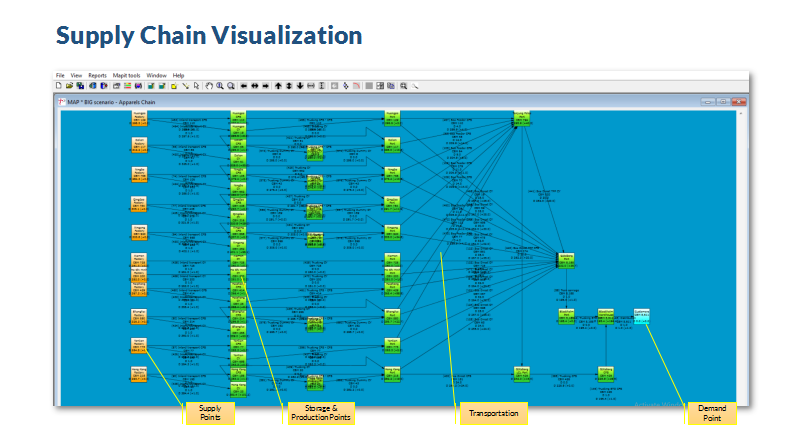

- It gives user-friendly node visualizations of the entire network to understand the cost/lead-time/carbon footprint at each stage of the SCM flow.

- Asset management tool to help you in the management of assets owned for your shipping and logistics operations.

- It supports both offline and online modes and allows multiple people to create/update and share scenarios. It is equipped with macro driven excel templates for data gathering for onsite investigation and progressive model building.

- It is equipped with wizards and model validators to help users find gaps in the model definition graphically and fix them quickly.

- An extensive supply chain modeling and optimization solution for cost, lead-time and carbon footprint analysis

- Inventory management solution and an analytics dashboard for making informed decisions.

- Uses sophisticated algorithms to calculate logistics costs, inventory holding costs & lead-time at each point of the chain

- Purchasing and inventory control

- Graphical Wizards for Model validation

- Provides insights on the volume flow, logistics cost, accumulated duty cost, accumulated lead-time, physical lead-time and others across and at each point of the supply chain

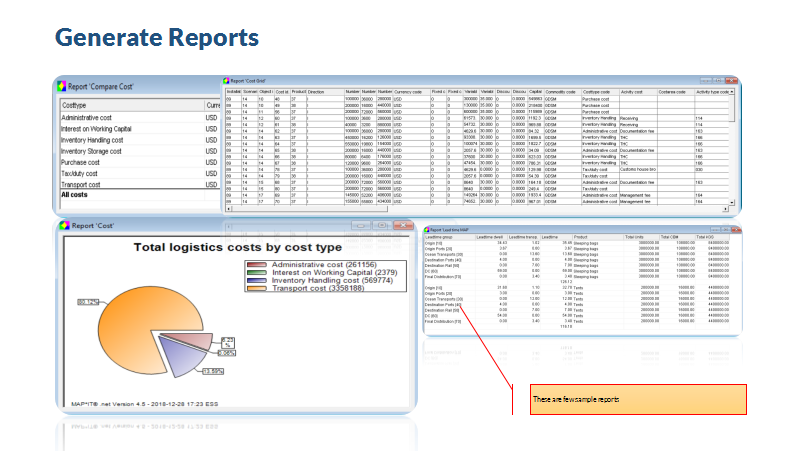

- Provides extensive scenario controlling parameters to carry out “what-if” scenarios and reporting

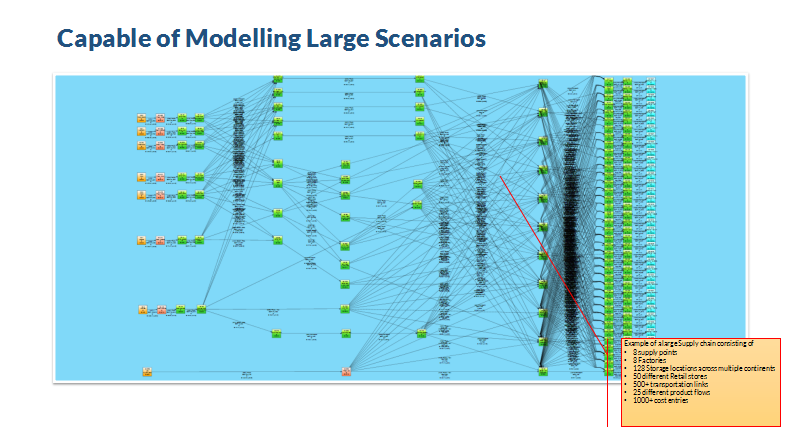

- Capable of modeling huge supply chains having tens of products, hundreds of storages, factories and stores and thousands of cost components

- Uses sophisticated algorithms for inventory lead-time and cost calculations including effects of handling time, safety stocks and impacts of inbound and outbound seasonality misalignment on stock build ups